COM high-strength phenolic cloth has excellent compressive strength, hardness, heat distortion temperature and excellent impact resistance, self-lubricating and wear-resistant properties.

MATERIAL INTRODUCTION

01 COM high-strength cloth-reinforced phenolic resin is based upon the thermosetting phenolic resin with

high-quality cotton fiber or other fibers or fabrics, added with appropriate amount of abrasion-reduction

addictives and finally finished with advanced laminating process.

02 COM high-strength cloth-reinforced phenolic resin, due to reasonable formulation and unique production

process, has excellent mechanical, chemical and physical performance. Compared with the frequently

used engineering plastic POM, nylon and Teflon, COM has excellent compressive strength, hardness,

heat distortion temperature, impact resistance and self-lubricating abrasion resistance.

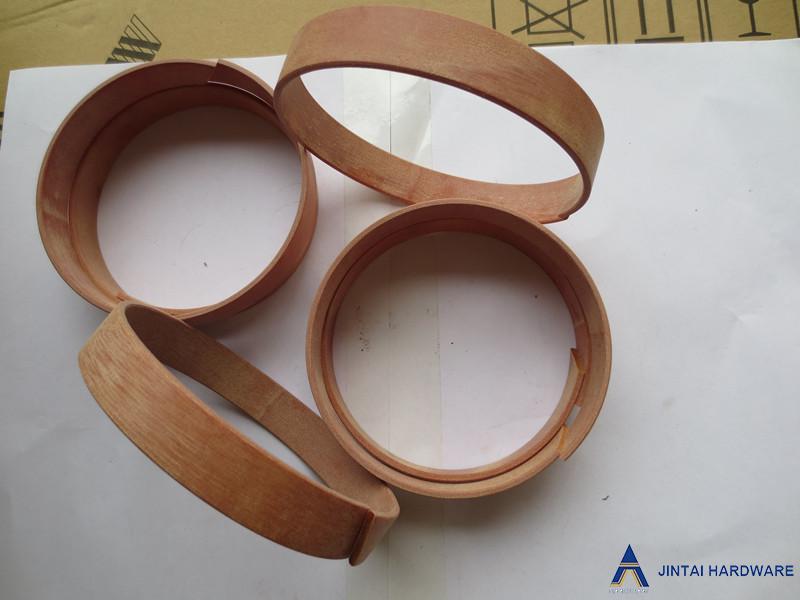

03 For many years, COM high-strength cloth-reinforced phenolic resin have been used in the production

of guide rings, support rings as well as various machinery pad and components such as bushings, thrust

plates, bearings for the cylinders of engineering machineries. Thanks to the excellent product

performance, this product has received lots of compliments from the users.

MATERIAL PROPERTIES

01 Outstanding compatibility

Since COM's molecular amount is mainly constituted by hydrocarbon chain molecules, which is similar

to the molecular structure of mineral. Therefore, COM has special lipophilicity and compatibility. Even

under conditions where the lubricating requirement is strict, such as frequent on-and-off, intermittent

movement, swinging movement, etc., where the lubricating oil film is difficult to form, COM can utilize

the small amount of grease to the maximum extend. Therefore, the maintenance interval and service

hours are greatly prolonged.

02 High temperature resistance

Compared with the frequently used engineering plastics, COM has high heat chemical stability and

heat mechanical stability. Normally the long- time working temperature of frequently used engineering

plastics is approx.80 -90 ℃ while COM's can be as high as 160 - 180 ℃ , which extends the application scope.

03 Excellent abrasion resistance

Compared with bronze, COM's hardness is lower and has excellent abrasion resistance. Therefore, the

engagement is easier and COM will not scratch the shafts. Used to make precision bearings, COM can

eliminate the complicated shaft-grinding process. Besides, the realistic contact area between the sliding

pairs is increased, which means a reduction of actual loads and wear.

04 High load capacity

Compared with the commonly used engineering plastics, COM has high mechanical strength. For instance,

the compressive strength of the former is approx .2-4 times greater than the latter, showing high load

capacity. Compared with bronze, the specific gravity of COM is 1/4 of the latter, showing high specific

strength.

05 Appropriate elasticity

COM is a material with elasticity. Compared with bronze and cast iron, COM is easy to assemble and has

vibration and noise absorbing functions, which can reduce the impact to the parts during the movement

and postpone the mechanical damages. Compared with normal engineering plastics, the plastic

deformation of COM, which impairs the supporting functions, is not likely to occur.

06 Excellent dimensional stability

Compared with the frequently used engineering plastic, COM's linear expansion coefficient is lower,

being 1/2 of them. Compared with nylon, COM's water absorption is lower. Therefore, for machinery

parts with high requirements on the precision of dimensions such as bearings, it is easier to control

the interference and fit clearance of COM products.

07 Excellent hydrophilic feature

COM containing special addictives has excellent hydrophilic features, able to work safely for a long time

under water-cooling or in water, where oil is completely absent, making the complicated sealed lubricating

device unnecessary.

TYPICAL APPLICATION

COM high-strength cloth-reinforced phenolic resin is suitable to make wearing parts for various machineries, such as bearings, bushings, thrust plates, guiding rails, guide rings, support rings, etc., where its unique features are shown. It is applied to the mechanical fields such as engineering machineries, mining machineries, petrochemical machineries, agricultural machineries aswell as engineering machineries for railways,bridges and water conservations.

- Ball Transfer Units

-

- Customized Series(FB) Ball Transfer Units

- PlasticNylon Series(NP,PJ,NL-A,B,C,N,M)

- One Way Roller(DX) Ball Transfer Units

- Machined Steel Bolt Mount Series(D)

- MSM Series(BCHA,BCHM,D-H) Ball Transfer

- MSM Series(BCHA,BCHM,D-H) Ball Transfer

- Felt Insert Series(FC) Ball Transfer Units

- Dis-chargeable OX Washable Heavy Duty

- Thread Body Mount (LW) Full Thread

- Bolt Mount Machined (NJ) Ball Transfer

- Inner External Spring Load (KSF,KSH,KS)

- Ball Downwards Machines (UK,UK-T,IK-B,IK-N)

- Machined Steel Heavy Duty (SPC,IA SI,SD)

- Machined Steel Heavy (SP,SP-FL,KSM,KSM-FL)

- Press Metal (CY-A,B,H,T,G) Ball Transfer

- Pressed Metal (CY-D,F,FL,X) Ball Transfer

- Conveyor Bearing Rollers

- Pressed Ball Roller Bearing Wheel

- Withdrawal Sleeve

-

- Withdrawal Sleeve AOH3200 Series

- Withdrawal Sleeve AOH3000 Series

- Withdrawal Sleeve AOH3100 Series

- Withdrawal Sleeve AOH2300 Series

- Withdrawal Sleeve AH3100 Series

- Withdrawal Sleeve AH3000 Series

- Withdrawal Sleeve AH3200 Series

- Withdrawal Sleeve AH2300 Series

- Withdrawal Sleeve AH300 Series

- Withdrawal Sleeve AH200 Series

(Chat Online)

(Chat Online)